GOLD WIRE VS COPPER WIRE BOND IN LED VIDEO WALL DISPLAYS

Gold Wire Bond vs Copper Wire Bond in LED Video Wall Panel Displays

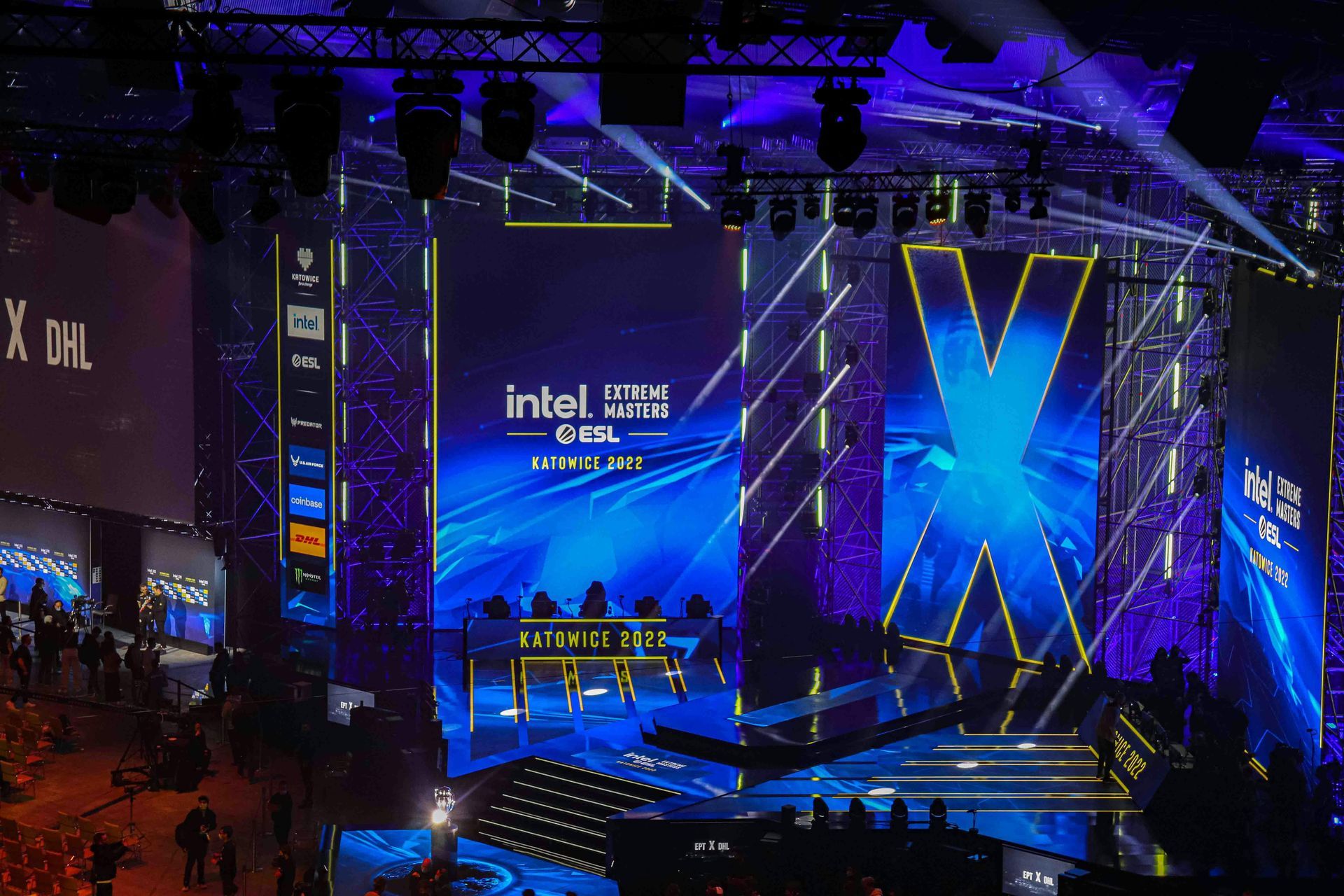

When selecting A LED video wall PRODUCT, the materials used in their construction play a critical role in performance, reliability, and cost. One of the most significant decisions manufacturers make is the type of wire bond material used to connect the LED chip to the package—commonly gold or copper. This blog will DIVE into the key differences between gold and copper wire bonding and their impact on LED panel displays.

What Is Wire Bonding?

Wire bonding is the process of creating electrical interconnections between the LED chip and the external circuitry using fine wires. These wire bonds ensure that electrical signals are transmitted efficiently, enabling the LEDs to function as intended. The two primary materials used for this purpose are gold and copper, each with its unique properties.

Gold Wire Bonding: Characteristics and Benefits

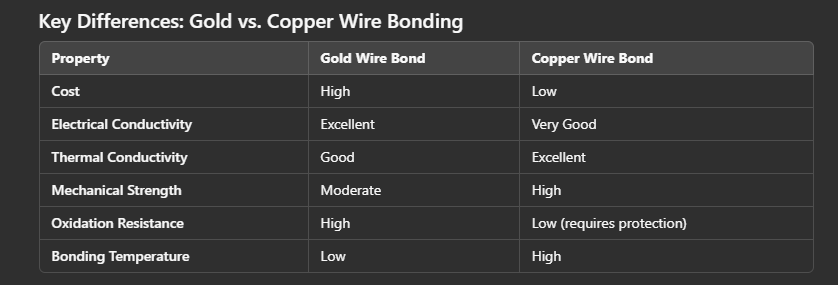

Gold has long been the standard material for wire bonding due to its excellent conductivity and resistance to oxidation. Here are the key advantages of gold wire bonding:

- Superior Reliability: Gold is highly resistant to corrosion and oxidation, ensuring long-term stability and performance even in harsh environments.

- Ease of Bonding: Gold’s malleability makes it easier to bond at lower temperatures, reducing the risk of damaging the LED chip during the manufacturing process.

- High Electrical Conductivity: Gold offers excellent electrical conductivity, ensuring minimal energy loss.

- Proven Track Record: Gold wire bonding has been used in LED technology for decades, making it a well-understood and reliable choice.

However, gold has its drawbacks, the most notable being its high cost. As the price of gold fluctuates, it can significantly impact the overall cost of LED video wall panels.

Copper Wire Bonding: Characteristics and Benefits

Copper wire bonding has gained popularity in recent years as a cost-effective alternative to gold. Here are the main advantages of copper wire bonding:

- Cost Efficiency: Copper is substantially cheaper than gold, reducing the material cost of LED video wall panels.

- Higher Mechanical Strength: Copper has greater mechanical strength than gold, making it more durable and less prone to breakage.

- Excellent Thermal Conductivity: Copper’s superior thermal conductivity helps to dissipate heat more efficiently, improving the longevity and performance of LED chips.

- Enhanced Current Carrying Capacity: Copper can carry higher currents compared to gold of the same diameter, making it suitable for high-power LED applications.

However, copper wire bonding is not without its challenges. Copper is more prone to oxidation, which can degrade performance over time if not properly managed. Additionally, copper requires higher bonding temperatures and specialized equipment, potentially increasing manufacturing complexity.

Choosing the Right Wire Bond Material

The choice between gold and copper wire bonding depends on several factors, including budget, intended application, and desired performance. Here’s a quick guide:

- Choose Gold Wire Bonding if reliability, ease of manufacturing, and resistance to environmental factors are top priorities. Gold is an excellent choice for premium LED video walls used in mission-critical applications such as control rooms or outdoor installations with extreme weather conditions.

- Choose Copper Wire Bonding if cost-effectiveness and high performance are essential. Copper is ideal for large-scale LED displays where budget constraints are a concern, such as retail or entertainment venues.

Both gold and copper wire bonding have their merits and challenges. Understanding their differences can help buyers make informed decisions when MAKING A PURCHASE. Whether you prioritize cost, durability, or performance, choosing the right wire bond material is key to ensuring the longevity and quality of your LED display.