The different types of LED lamp chips

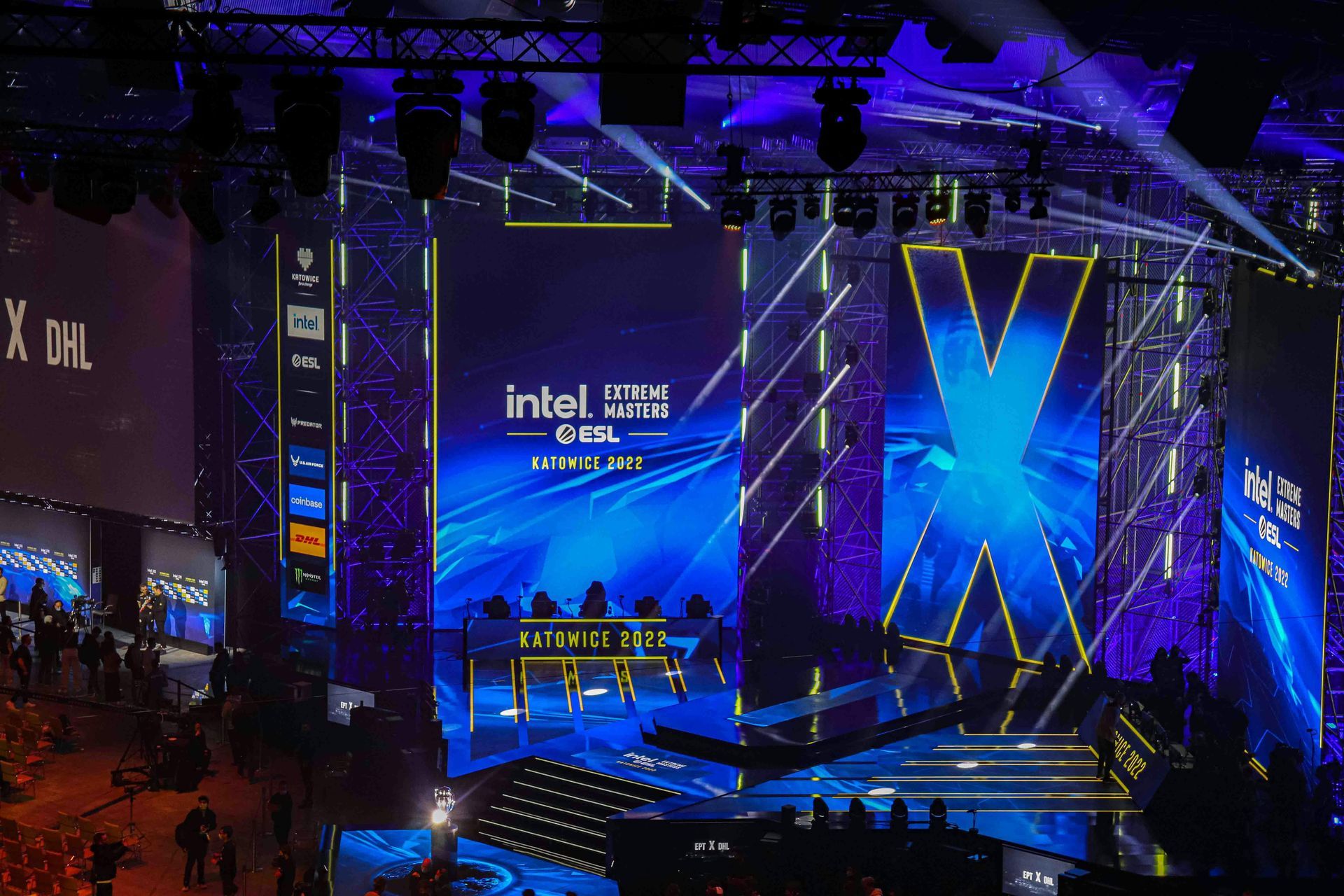

Exploring LED Lamp Chips in LED Video Wall DISPLAYS

In the world of high-end LED video wall displays, the quality of the final product heavily depends on the type of LED lamp chips used. These chips are the core components that determine the brightness, color accuracy, power efficiency, and lifespan of the display. Let’s explore the different types of LED lamp chips commonly used in these sophisticated displays.

1. SMD (Surface-Mounted Device) LED Chips

SMD LED chips are the most commonly used in modern video walls. They are mounted directly onto the surface of a printed circuit board (PCB) without the need for leads or wires. This allows for compact, lightweight, and highly efficient designs.

Key Features:

- Available in different sizes (e.g., SMD1010, SMD2121, SMD3535).

- Excellent color uniformity and wide viewing angles.

- High brightness levels, making them ideal for indoor and outdoor video walls.

Applications: SMD chips are widely used in both indoor fine-pitch displays and large outdoor screens due to their versatility and performance.

2. COB (Chip-on-Board) LED Chips

COB technology involves mounting multiple LED chips directly onto a single substrate. This design enhances thermal conductivity and reduces heat buildup, resulting in improved efficiency and lifespan.

Key Features:

- Superior heat dissipation.

- High reliability and resistance to environmental factors like moisture and dust.

- Seamless and uniform light output with minimal glare.

Applications: COB LED chips are favored for ultra-fine pixel pitch displays used in control rooms, broadcasting studios, and other environments requiring high resolution and durability.

3. DIP (Dual In-Line Package) LED Chips

DIP LED chips are the traditional type, featuring two leads that are inserted through holes on a PCB and soldered. While they have largely been replaced by SMD and COB technologies, they are still used in certain applications.

Key Features:

- High brightness and robustness.

- Simple and cost-effective manufacturing process.

- Limited color range and viewing angles compared to newer technologies.

Applications: DIP chips are commonly used in outdoor video walls and large digital billboards where extreme brightness is crucial.

4. MicroLED Chips

MicroLED technology is a cutting-edge advancement in the LED industry. These chips consist of microscopic LED arrays, offering unparalleled brightness, contrast, and energy efficiency.

Key Features:

- Exceptional brightness and contrast ratio.

- Ultra-low power consumption.

- Excellent durability and longevity.

Applications: MicroLED chips are ideal for next-generation video walls in luxury environments, such as high-end retail, museums, and premium home theaters.

5. MiniLED Chips

MiniLED chips are a transitional technology between traditional LED and MicroLED. They offer many of the benefits of MicroLED but are easier to produce and more cost-effective.

Key Features:

- Improved brightness and contrast compared to standard SMD.

- Finer pixel pitch for better resolution.

- Enhanced HDR performance.

Applications: MiniLED chips are commonly used in professional-grade video walls and high-performance consumer displays.

Conclusion

The choice of LED lamp chips for a high-end video wall depends on factors like the intended application, desired resolution, brightness, and budget. While SMD and COB technologies dominate the current market, innovations like MicroLED and MiniLED are pushing the boundaries of what’s possible in visual display technology. By understanding these options, businesses and integrators can select the best solution for their specific needs, ensuring stunning visual performance and lasting reliability.